The Future of Heavy Vehicle Steering is Electric.

Cascade Drives' TruEPS™ technology eliminates hydraulics, enabling safer, more efficient, and autonomous commercial transportation.

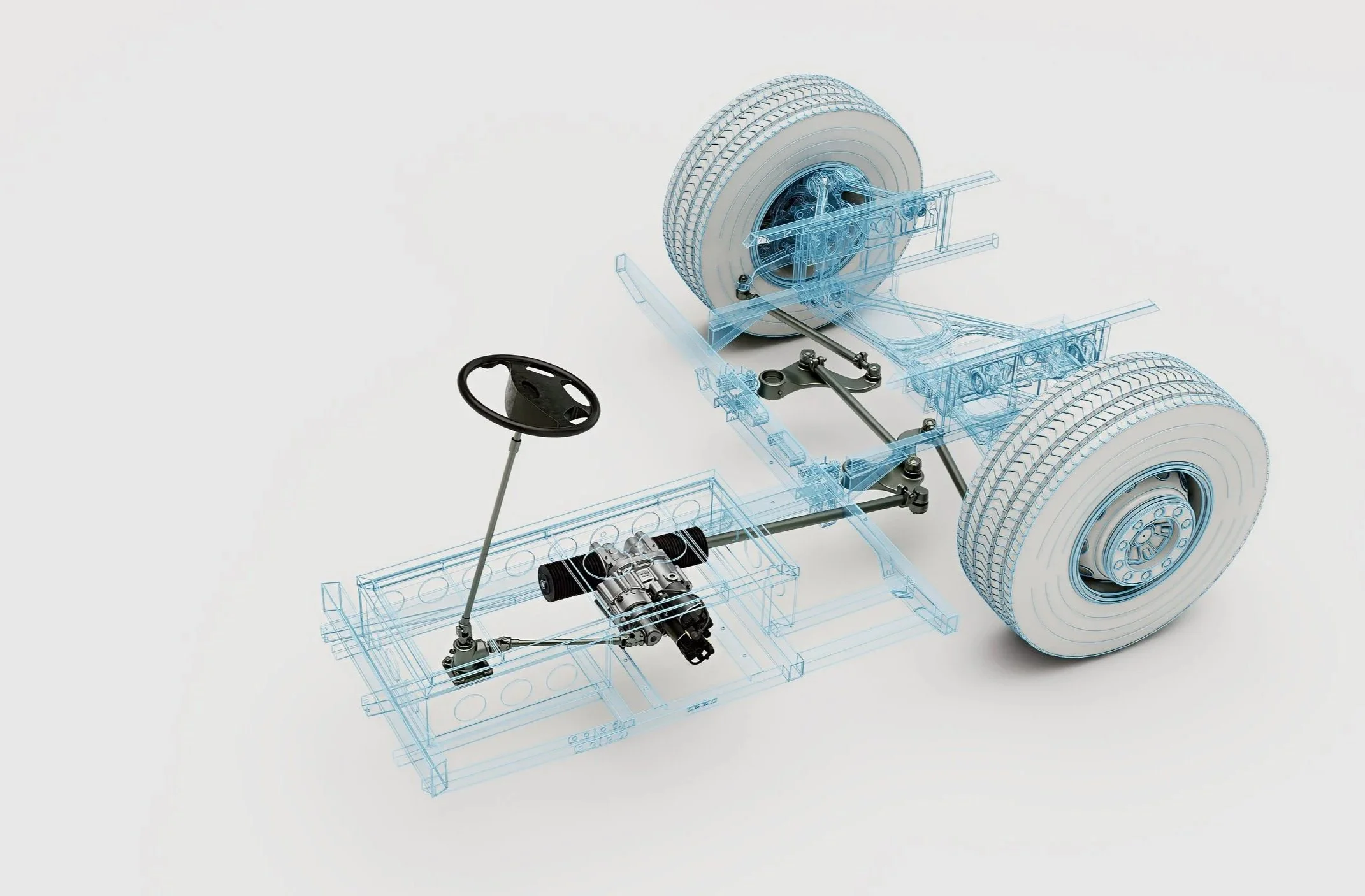

Visualization of TruEPS™ integrated into a bus with IFS axle .

Some of our Customers

The Steering Bottleneck

Outdated hydraulic steering is holding back the future of commercial transportation.

Maintenance Intensive

Traditional hydraulics mean fluid leaks, degradation, and regular replacement.

Design Limitations

Bulky systems restrict vehicle packaging and innovative designs.

Energy Inefficient

Constantly consume energy, impacting fuel economy and EV range.

Autonomy Barrier

Lack the precise control and redundancy needed for autonomous operation.

The Cascade Drives Solution

TruEPS™: Reinventing Steering

Our patented CD Gear technology delivers true electric power steering, specifically engineered for the demands of heavy vehicles and autonomous operation.

☑ Fully Electric Operation

Eliminates complex hydraulics for a cleaner, more efficient system.☑ ASIL-D Safety - ready

Meets the highest automotive safety integrity for critical functions.☑ Native Steer-by-Wire

Designed from the ground up for seamless autonomous integration.TruEPS™ system showcasing our patented CD Gear technology, dual-motor redundancy, and compact design optimized for heavy vehicle applications

The TruEPS™ Advantage

Discover tangible benefits that drive efficiency, safety, and innovation.

Autonomous Ready

ASIL-D - ready with native steer-by-wire capabilities for safe self-driving.

Design Freedom

Compact electric system enables flexible packaging for next-gen vehicle platforms.

Maintenance Free

No hydraulic fluid means fewer wear components and significantly reduced upkeep.

Enhanced Efficiency

Lower inertia and on-demand operation reduce energy consumption.

Precise Control

Electric actuation offers superior steering precision and responsiveness.

Future-Proof

Software-defined characteristics allow for updates and adaptability.

Powering the Future Across Industries

Our versatile TruEPS™ technology is adaptable to a wide range of commercial vehicle applications.

Heavy Trucks (Class 6-8)

Enabling autonomous capabilities and significantly reducing maintenance.

Buses & People Movers

Providing precise control for enhanced passenger comfort and safety in urban transit.

Autonomous Trucks

The core steering solution for self-driving platforms requiring utmost reliability.

Electric Platforms

Optimizing space and efficiency for next-generation EV skateboard designs.

Powering the Future Across Industries

Our TruEPS™ can be integrated with independent front suspension or with traditional rigid axle pitman arm to draglink mounting

Traditional Rigid Axle

Most Class 6-8 trucks still use rigid axles. What’s special about our TruEPS steering system is that it allows for “center mount position”.

Our compact fully integrated EPS gives you all the design freedom your designers ever wished for.

Of course we are also supporting the traditional mounting position as you can see in the image below.

Independent Front Suspension

For low-floor buses it’s essential to optimize for minimized entry height. Independent front suspension like in this example from our partners eVersum is the preferred solution.

Our TruEPS system has strong advantages for this axle design with its super compact design and integrated components.

Ready to Drive the Future?

Partner with Cascade Drives to integrate cutting-edge electric power steering into your heavy vehicles and autonomous platforms.