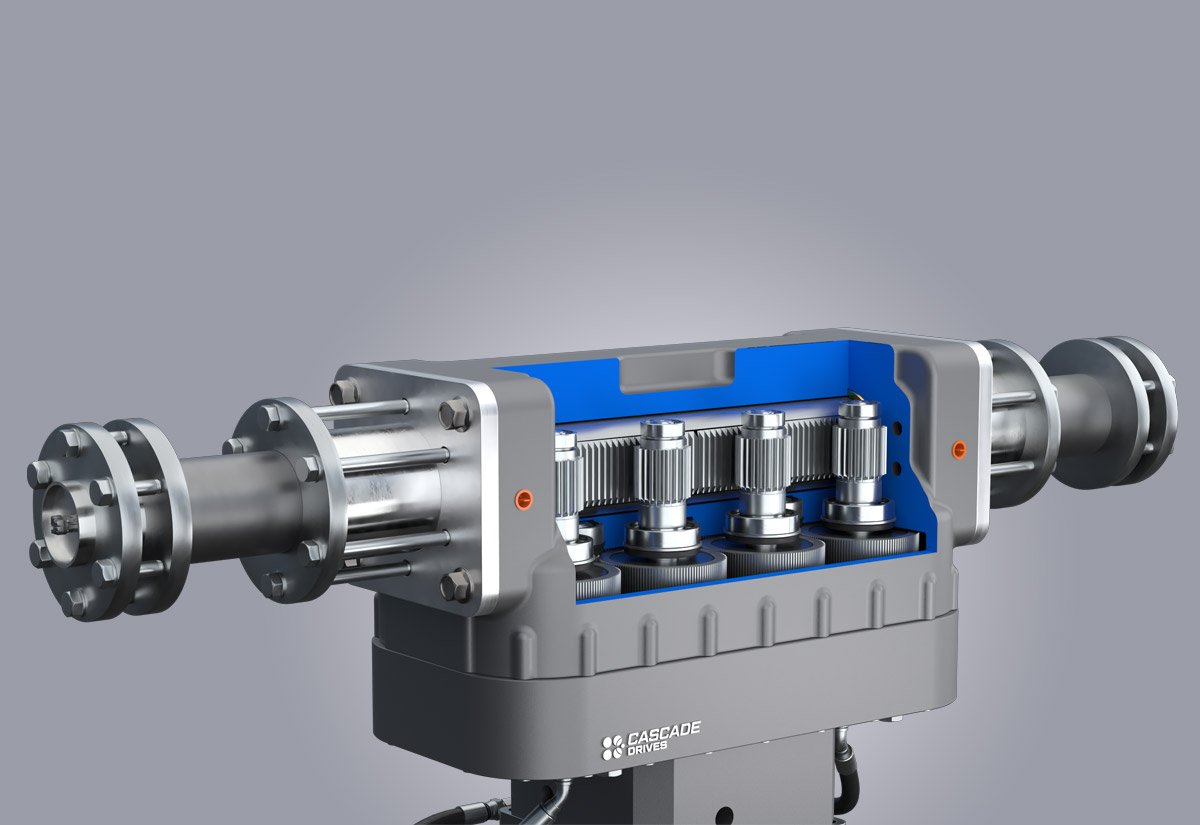

Electromechanical pump drive

Increase cutting speed in your water jet cutting process.

Our rack- and pinion-based pump drive offers outstanding positioning accuracy, variable stroke speed and length. A unique solution that significantly improves productivity and efficiency without the use of hydraulic fluids.

Electrical actuators in industrial applications!

Compact design

Plug-and-play replacement for most hydraulic actuators.

Variable stroke length

Enables longer strokes for higher efficiency.

Variable stroke speed

Enables better control of pressure and flow.

No hydraulic oil

Reduces maintenance needs and eliminates risk of hydraulic oil leakages.

A revolutionary pump

Suitable for any pumping application where high demanding production cycles, high pressure, and extreme position accuracy are required.

The pump can be easily adapted to any existing plunger interface turning a hydraulic pump into an electromechanical pump.

Core components or part of system are available for pump manufacturing OEM´s. Cascade Drives offers knowledge of both hardware and software engineering.

Take control of your pressure cycle

Cascade Drives’ pump drive technology offers a new way of delivering cost-efficient high pressure for a variety of industrial applications.

With Cascade Drives rack and pinion-based technology, you not only save energy, but you can achieve a new level of control that just isn’t available with traditional pumps. A combination of high positioning accuracy and a fully customized speed and load curve enables an optimized performance resulting in improved pressure cycle and thereby productivity.

Cascade Drives pump drives are designed for handling back-pressure and sudden pressure peaks over and over again, ensuring the reliability of your production.

High-pressure pump applications

-

Waterjet cutting

Increase your cutting speed with higher water pressure on demand.

-

High-pressure food processing

Reduce operating costs with a hydraulic oil-free system.

-

Hot isostatic pressing

Improve productivity with reduced cycle time and maintenance requirements.

-

Injection molding

Improve productivity and quality of molding process by variable stroke speed.

-

Hydrogen

Upgrade your diaphragm or piston compressor for higher efficiency.

-

Oil and gas

Reduce size and improve control on your reciprocating pumps.

-

Want to know more?

Don’t hesitate to contact us for more information. We’ll be happy to discuss how your industrial applications can benefit from Cascade Drive’s technology.

-

Andreas Aspell

+46 73-981 53 57

andreas.aspell@cascadedrives.com